Ecosågen Twin 400 has been manufactured for almost 20 years and has been exported to many countries. Continuous product development means that our products always are in the forefront of innovative technology, reliability and performance. Ecosågen lack any bearing caps and belts. Robustness is optimal, and need minimal maintenance. Ecosågen is not only effective, but also fun to use.

The portable circular sawmill is fully tested and third-part certified by the Swedish Machinery Testing, SMP, to ensure that the product meets all safety standards and CE standards and are also patented with PRV.

We use Swedish alloy steel plate from in our products. After laser cutting, bent parts and the necessary holes are threaded. The parts are welded in the fixture. The surface treatment begins with removing all the grease and laser oxide scale. After that galvanization and finally coated with a durable powder coating.

EEE stands for Ergonomic, Economic and Ecology. In our sawconcept we have managed to combine these factors. The ergonomics are by far, meaning you can cut long hours without becoming fatigued, especially due to the hydraulic log handling, laser, and the low noise level. The economy is achieved by a good relation price-performance and minimal maintenance costs. Finally, an ecological product, driven by electric power, preferably green one, with low operating costs, high production per input KWH and minimal power loss.

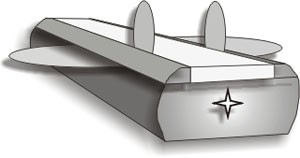

Construction

Saw frame is constructed of laser cut sheet metal profiles. On this framework, a mobile saw unit is moving. The feeding of the saw unit is variable and is powered by a hydraulic motor by a pull wire in the saw’s corner. An integrated hydraulic power unit is located in the back of the saw frame.

The saw unit is built on a heavy duty motor plate, in which two motors are mounted vertically. On every electric motor output shaft there is a saw blade attached. No transmissions are required, the electrical power is transfered right into the saw blade. Above the blade, there are two milling cutterblades attached which reduces the stock if it is too coarse.

The saw unit moves up and down stored on two vertical guide rails. Movement is performed by a hydraulic cylinder. A measurement scale and a laser indicates where the log will be cut.

The sawmill is operated entirely from one place where all functions are gathered. It provides a convenient and labor-saving methods, and a safe workplace.

Function

The hydraulic log lifter lifts quickly and elegantly the log so that it can easily be rolled into the sawframe. The loglift now serves also as a table for boards and other material that has been sawed. The work will be safer and the risk for injuries decreases as the logs can be simple wared at ground level.

The sawmill is equipped with 3 pairs of hydraulic clampers, that fasten the log firmly during sawoperation. Clampers can be easily tilted in the appropriate position and is tagged at the top to grip firmly if there is snow and ice on the log

The clampers are also holding the log in right position in order to ensure the block cut in correctly squared.

When the block is sawed on three sides, clamper is placed in lower position which allows the last board can be cut down to 25 mm.

The clampers are moving symmetrical to the center of the sawframe so while the log is fixed, it is also centered on the frame, perfect for one man operation. Thanks to the absolute fixation, the log can be cut with a precision that is outstanding.

The hydraulic log rotator turns the log rapidly between the different saw moments.

The log rotator consists of a toothed chain driven by a hydraulic motor, infinitely variable both in terms of speed of rotation direction.

Saw blades

Ecosågen Twin 400 saws with two horizontally mounted blades. The blades are overlapping each other with about 5 mm. Each blade is fixed to a spindle with four screws. The saw blade can be easily removed using an insex wrench, or even faster using a battery-powered screwdriver.

Blade diameter is 400 mm and cutting width 4.1 mm. Our saw blade is made of high-alloy steel from Uddeholm and is equipped with carbide teeth from Sandvik Coromant. Together, this superb cutting ability gives great durability and long grinding interval.

Using twin blade system, problems due to sawing under winter climate conditions are reduced to a minimum.

Ecosågen Twin 400 saws easily both in frozen and half frozen wood, the saw blade can be used year round.

The teeth are alternately grinded so that each teeth cuts only half the average. The sawdust can then expand laterally without penetrating the wood and cause friction. This specially designed saw blade is therefore extremely easy going, in combination with two outer and two inner’s cuts that cleans out dust and twigs from the kerf.

Theory

Ecosågen works with two horizontally mounted saw blades. The log lies still during sawoperation, fixated with 3 pairs of hydraulic clampers .

Ecosågen works with two horizontally mounted saw blades. The log lies still during sawoperation, fixated with 3 pairs of hydraulic clampers .

Saw blades are slightly overlapping each other by about 5 mm. The direction of rotation of the blades is from center of the log and goes out through the bark. Any dirt and dust drawn thus never in log, but is thrown out into the open air. Grinding range is about 100-150 logs.

Cutting tooth starts its work in parallel with the fibers where the initial cutting resistance is lowest. The surface of the sawn material is thus very smooth, ”almost as planed”.

What determines the amount of chips that can be cut by each tooth is the chip space area of the blade. If chip space is full, increases temperature and energy loss occurs. The way that chips must be transported is therefore minimized. Twin blade is very easy going, which explains the low power requirements. With the small diameter of each blade is also apparent that the friction on the blade’s edge is minimal. Compression wood is not a problem, it is extremely rare that the blades are stuck. A prerequisite for precision cutting with low power requirements are that the log is at rest and the absence of vibration in the moving saw unit, and that the cutting element is steady and not change direction vertically below sawoperation. Here is the saw blade superior for example bandsaw where unfavorable movements caused by soft wood alternating with hard knots make the cut will be both wave and fringe with poor dimensional accuracy and boring downtime as a result.

occurs. The way that chips must be transported is therefore minimized. Twin blade is very easy going, which explains the low power requirements. With the small diameter of each blade is also apparent that the friction on the blade’s edge is minimal. Compression wood is not a problem, it is extremely rare that the blades are stuck. A prerequisite for precision cutting with low power requirements are that the log is at rest and the absence of vibration in the moving saw unit, and that the cutting element is steady and not change direction vertically below sawoperation. Here is the saw blade superior for example bandsaw where unfavorable movements caused by soft wood alternating with hard knots make the cut will be both wave and fringe with poor dimensional accuracy and boring downtime as a result.

Technical data

| Max log length | 6,2 m |

| Max log diameter | 50 cm |

| Thinest board | 1,5 mm |

| Max square | 300 x 300 mm |

| Max board | 75 x 300 mm |

| Kerf | 4,1 mm |

| Hydrauic system | 170 bar system preasure |

| Jacks | 6 mechanical |

| Log lift | Hydrauliic |

| Log clampers | Hydrauliic, 3 pair |

| Log rotator | Hydraulic |

| Feed of saw unit | Hydraulic, 0-1 m/s |

| Aiming point | Laser |

| Saw blades (2 pcs) | Two x 400 mm carbide tipped |

| Såg engine (2 pcs) | ,5 kW with integrated disc breake |

| Portable sawmill | 50 mm trailer coupling for car |

| Weight portable sawmill | 1500 kg |

| Length portable sawmill | 10,1 meter |

| Power requirements | 32 A 400 V |

| Capacity | 8-12 logs per hour |